DTZ-TS Temperature Switch Automatic Calibration System

Request a Quote

Or whatsapp +8618853850621

Description

Download

Overview:

DTZ-TS temperature switch automatic calibration system is an intelligent testing platform that deeply integrates multidisciplinary technologies, adopting three core technologies: professional software algorithms, high-precision temperature measurement terminals and fully Automatic testing architecture.The system is designed for industrial temperature switches and temperature control components, and realizes unattended testing from raw data collection, multi-dimensional feature analysis to intelligent certificate generation through Automatic testing process, which significantly improves the efficiency of metrological testing and reliability of the results.The system consists of four parts:

1. Based on mK-level temperature control precision DTMC-mK301G thermometer;

2. Intelligent precision thermostat bath;

3. Temperature switch scanner;

4. Integrated calibration management software, forming a “perception-analysis-execution” closed-loop system.

Features / Advantages

1.Flexible adaptation of multiple types of temperature switches

Compatible with various types of temperature switches such as active switches, passive switches, normally closed switches, normally open switches, etc.

2. Integrated standardized uncertainty calculation module

Strictly follow the metrological verification regulations "JJF 1632-2017 Temperature Switch Temperature Parameter Calibration Specification", built-in synthetic standard uncertainty and extended uncertainty automation calculation engine, Automatic implementation of the extended operation, to ensure that the results of the measurement uncertainty in full compliance with the mathematical model required by the regulations (k = 2), and to provide a traceable record of the computation process and the verification of the report generation function.

3.Highly accurate multi-channel data acquisition

Equipped with high-precision intelligent multi-channel pyrometer, the resolution of the standardizer data reading up to 0.0001; configuration of 10 channels at the same time calibration, to ensure the high accuracy and reliability of temperature measurement, to meet the stringent requirements of precision calibration.

4.Intelligent integration of equipment components

Temperature switch scanning device can be real-time power supply for the inspected switch, support manual and Automatic two test modes, and through the channel indicator lights synchronously display the switch action status, realizing the intelligent integration of power supply, test and status reminder to enhance the inspection efficiency and operation intuition.

5.Intelligent temperature control and condition detection integration

Real-time detection of changes in the state of the temperature switch and precise control of the temperature rise and fall. process of the thermostat tank, realizing the synchronous automation of temperature regulation and switch detection, ensuring efficient and accurate calibration process.

6.Integrated intelligent temperature rate control

Adopt PID regulation algorithm to implement dynamic rate constraints (≤1℃/min) for the heating/cooling process, through real-time power adjustment and temperature gradient monitoring, to ensure a smooth and controllable temperature change process, to avoid measurement errors caused by violent temperature fluctuations, and to meet the stringent requirements of the metrological calibration regulations for the rate of heating and cooling.

7.Intelligent Computing and Judgment Integration

Automatically calculate the action temperature error and on-off temperature difference of the temperature switch, and intelligently determine its effective range based on the preset standard, realizing the rapid analysis of the detection data and the determination of the results.

8.Enhanced temperature field stability control

Multi-order PID algorithm with real-time temperature feedback regulation mechanism is adopted to ensure that the system reaches the specified fluctuation threshold within the set time (≥10min) after entering the steady state from the heating stage, and maintains long-term stability through dynamic compensation strategy to meet the technical requirements of the metrological verification regulations on the stabilization time.

9.Real-time data and status monitoring

The interface displays and updates the standardizer data and task status in real time, providing intuitive operational feedback and dynamic information, ensuring that the user is always in control of the calibration process and key parameters, and enhancing operational convenience and transparency.

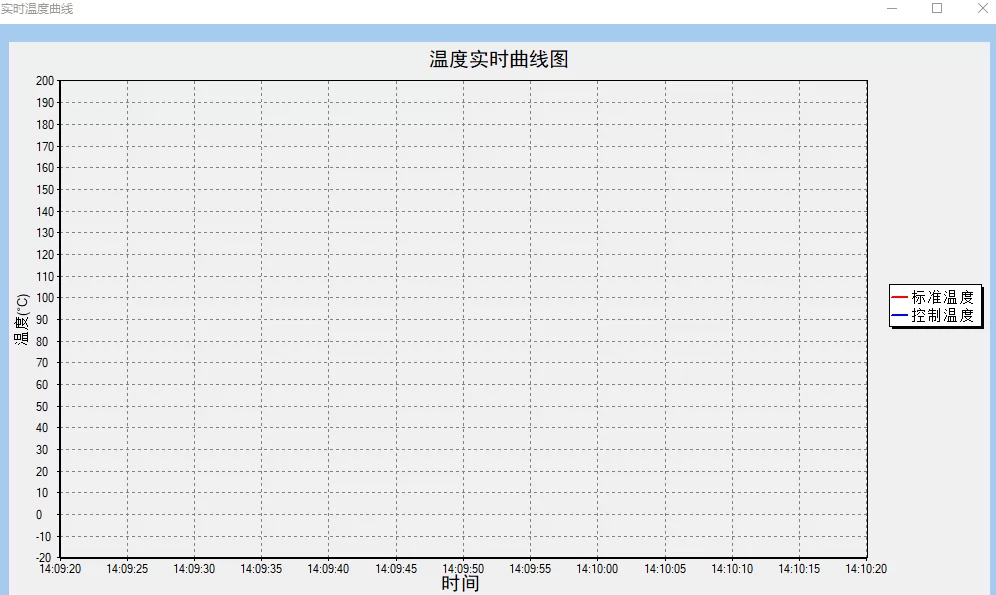

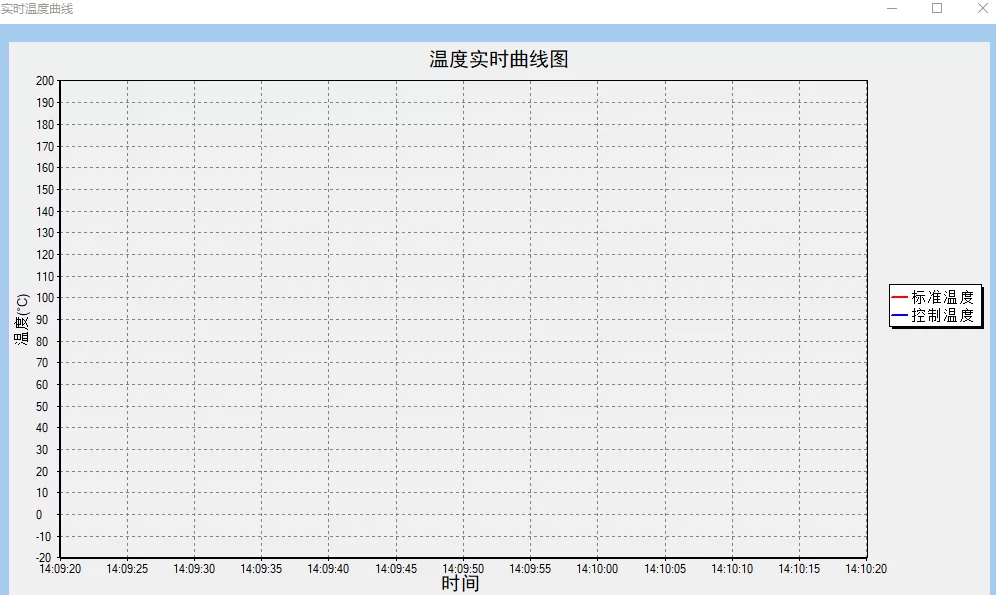

10.Dynamic tracking and history of temperature profiles

Real-time update of the temperature change curve, support for viewing the historical curve data, to help users visualize and analyze the temperature trend, providing visual reference and data traceability for the calibration process.

11.Easy wiring and remote expansion

Adopt simple wiring design, support ultra-fast sensor wiring, and reserved extension cable interface, to meet the needs of long-distance testing, significantly improve the convenience of field operation and adaptability of the test scenario.

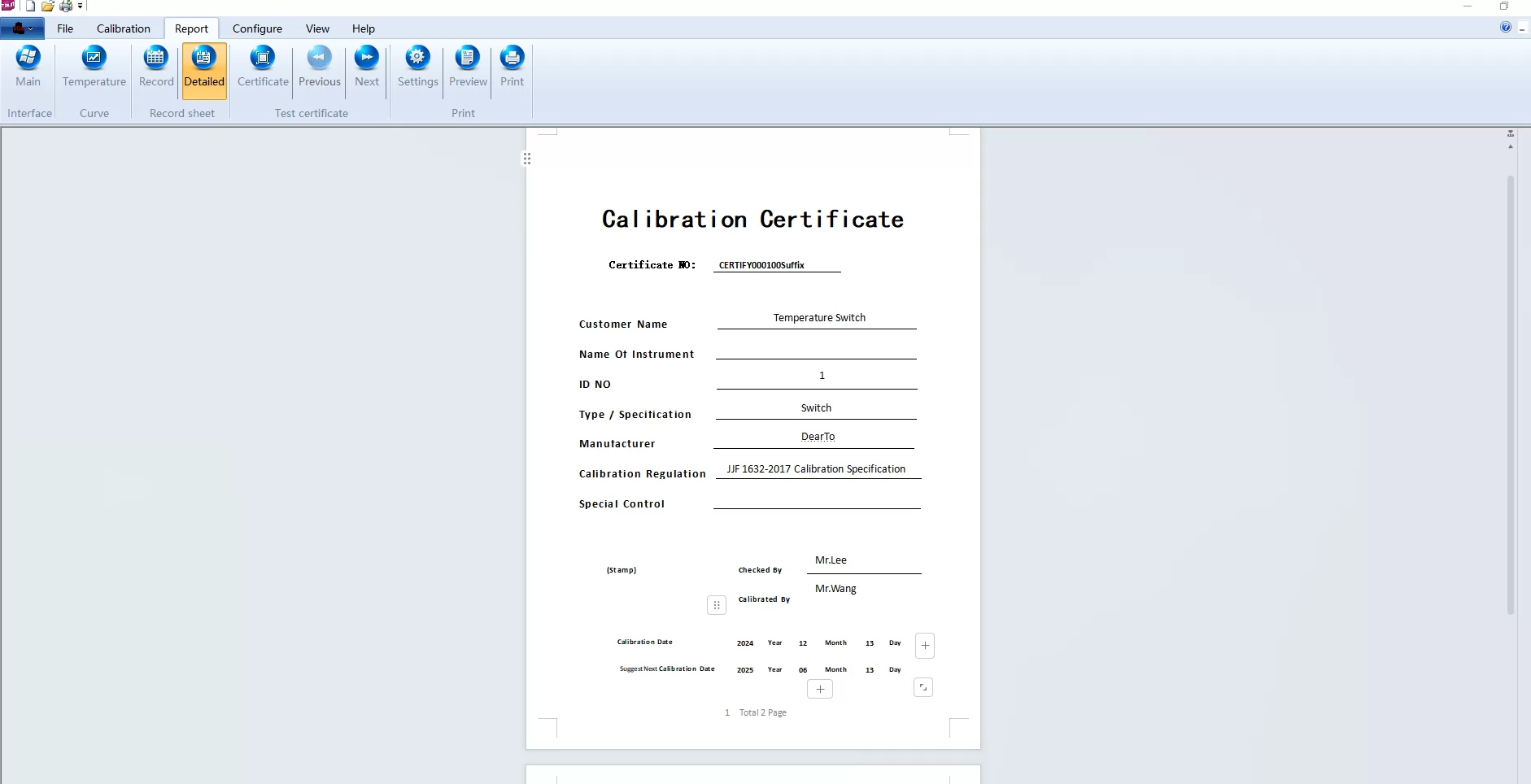

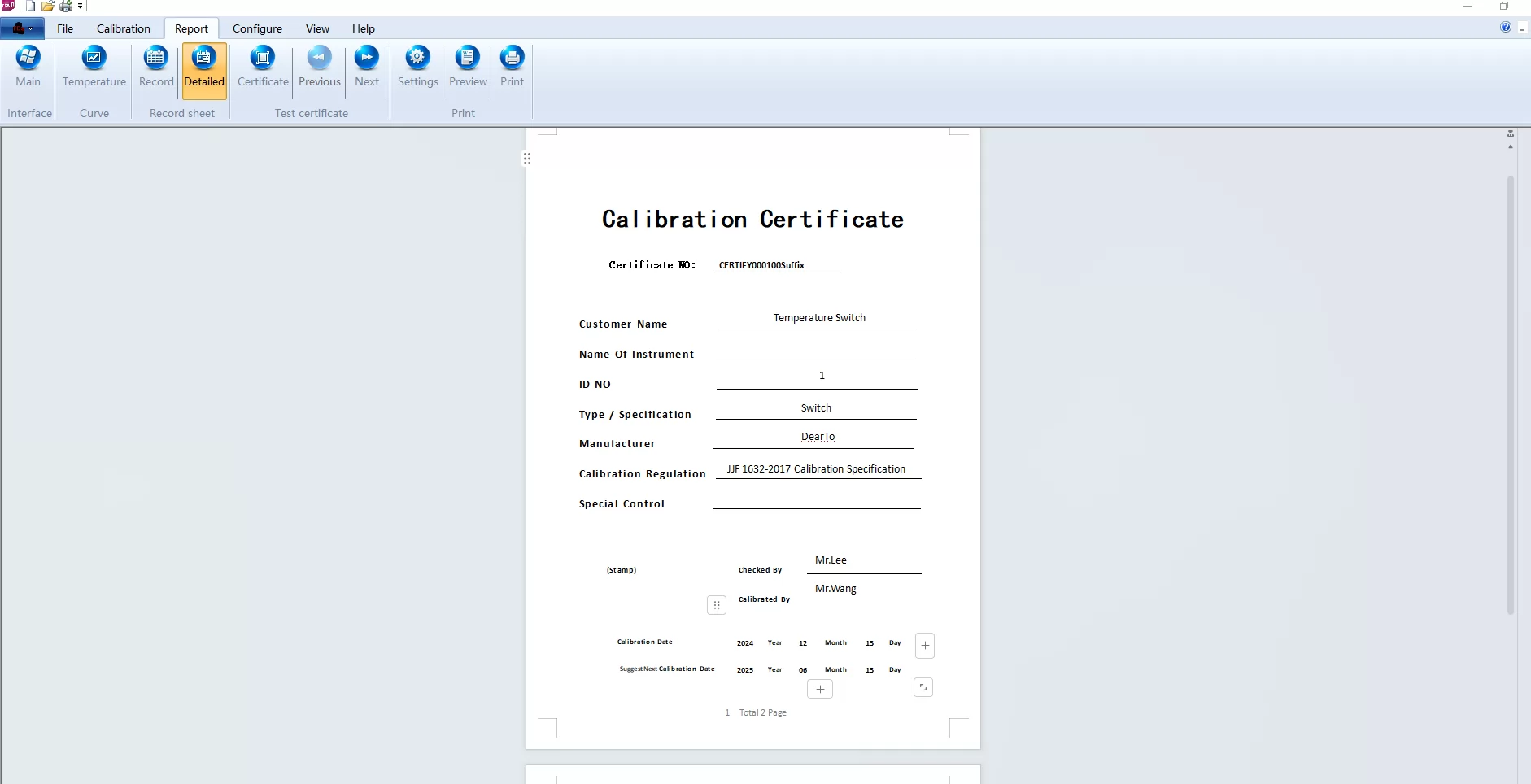

12. Intelligent report generation and output

Automatically generates the testing record sheet, supports the export and printing of original records and calibration certificates, realizes the standardized management and convenient output of testing data, and meets the demand of standardized calibration process.

13.Efficient history search

Support a variety of keyword search function, users can quickly query the history records, to achieve the accurate positioning of data and flexible access to enhance the efficiency and convenience of data management.

14.Multi-protocol communication compatible

Support RS232, RS485, Type-C and other communication modes to ensure seamless connection and data transmission with various devices, meet the communication needs of diversified industrial scenarios, and enhance system adaptability and expandability.

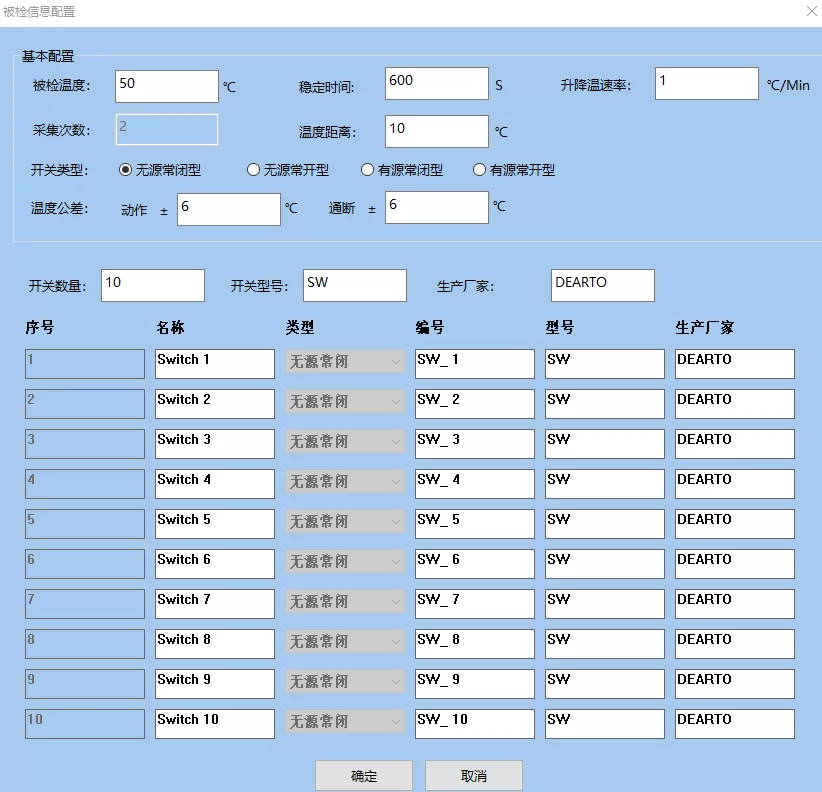

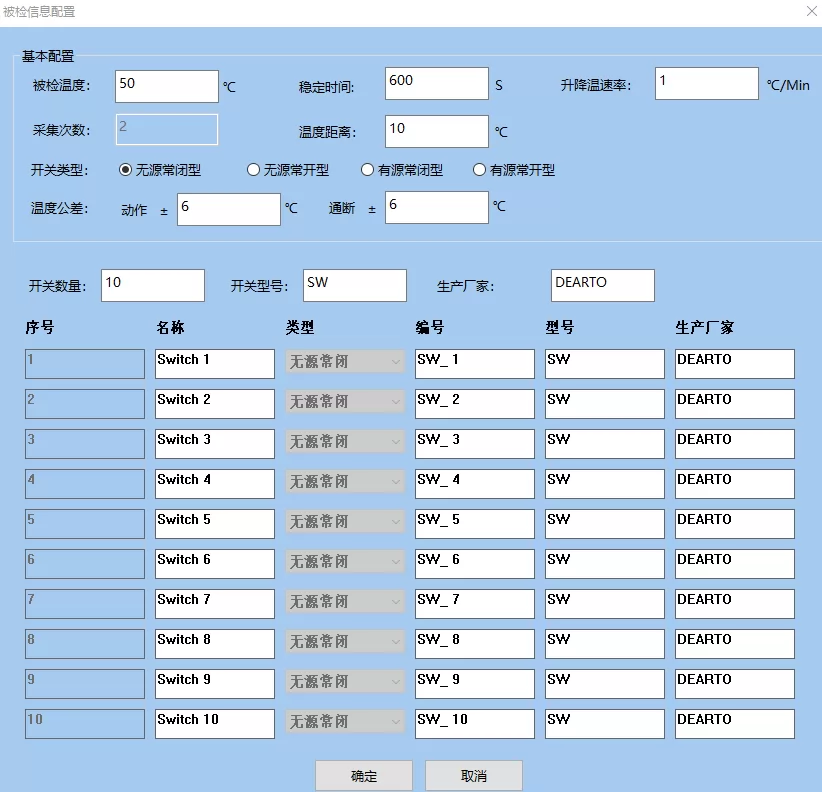

Full parameter customization

Support the user to set the calibration temperature, acquisition times, stabilization time, temperature distance, temperature rate, temperature switch type, number, model, temperature tolerance and manufacturer and other basic information, to provide a highly flexible configuration of the detection parameters, to meet the needs of diversified testing and personalized operating experience.

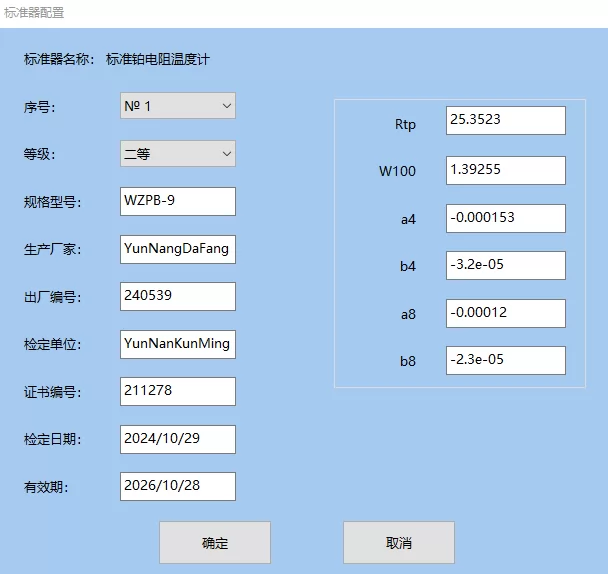

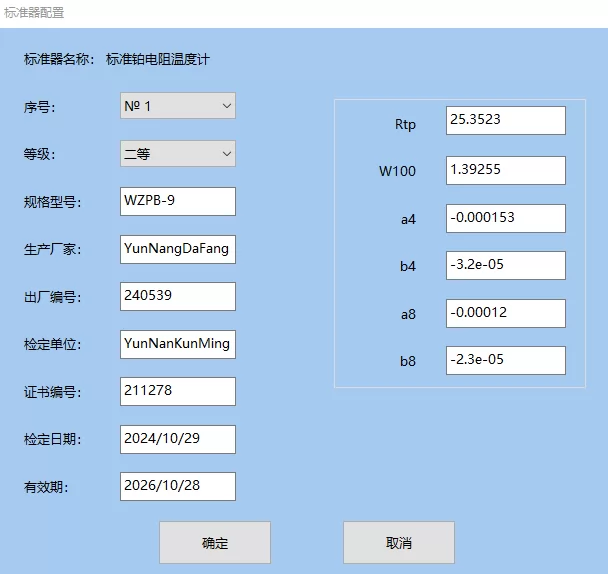

Intelligent management of standardizer information

The system supports the customization of the standard apparatus number, grade, model, manufacturer, factory number, calibration location and expiration date and other information, and can be programmed into a number of standard apparatus number, calibration directly select the corresponding number can be achieved standardized management of standard apparatus information and convenient call to enhance the accuracy and efficiency of the calibration process.

Intelligent monitoring and visualization of the whole process

The main interface of the system dynamically displays the current temperature of the standard and the thermostat tank, the set temperature, the temperature difference, the number of calibrations, the number of readings on the digital meter, the rate of temperature rise and fall, the inspected temperature point and the system running time and other key parameters, which achieves all-around real-time monitoring of the inspection process and data visualization, ensuring accurate and efficient operation.

Intelligent temperature control and real-time tracking of task status

The system Automatically determines the temperature switch status and accurately controls the temperature rise and fall of the thermostat tank, while the task bar real-time display of key information such as warm-up time, temperature rise time, temperature fall rate, interruption status and task completion, etc., realizing the intelligent management and dynamic monitoring of the testing process and ensuring the operation to be efficient and transparent.

Dynamic tracking and history of temperature profiles

Temperature change curve real-time update, you can view the history of the curve changes.

The curve interface updates the temperature data of the standardizer and the thermostat bath in real time.

Intelligent computing and reporting integrated management

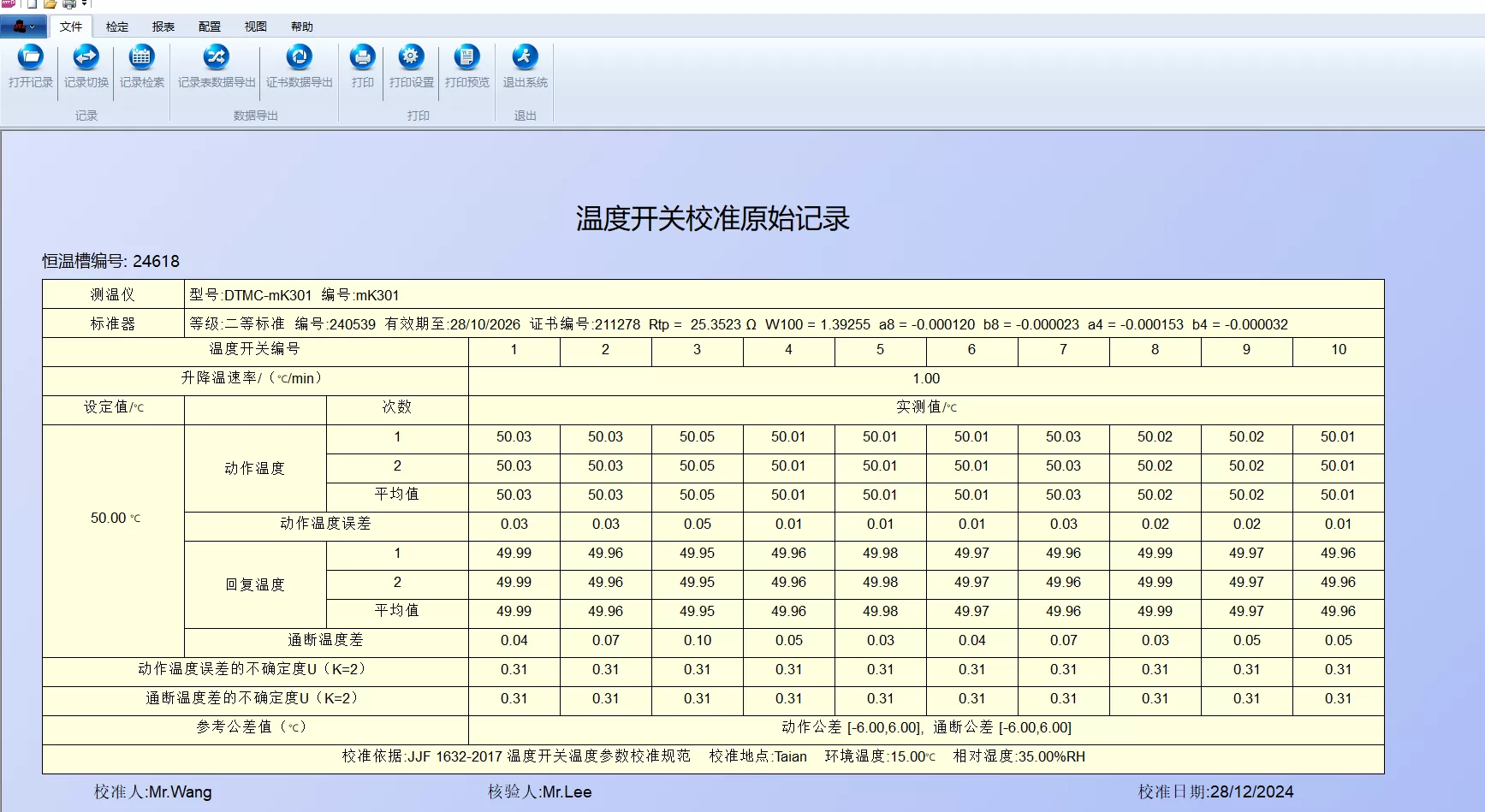

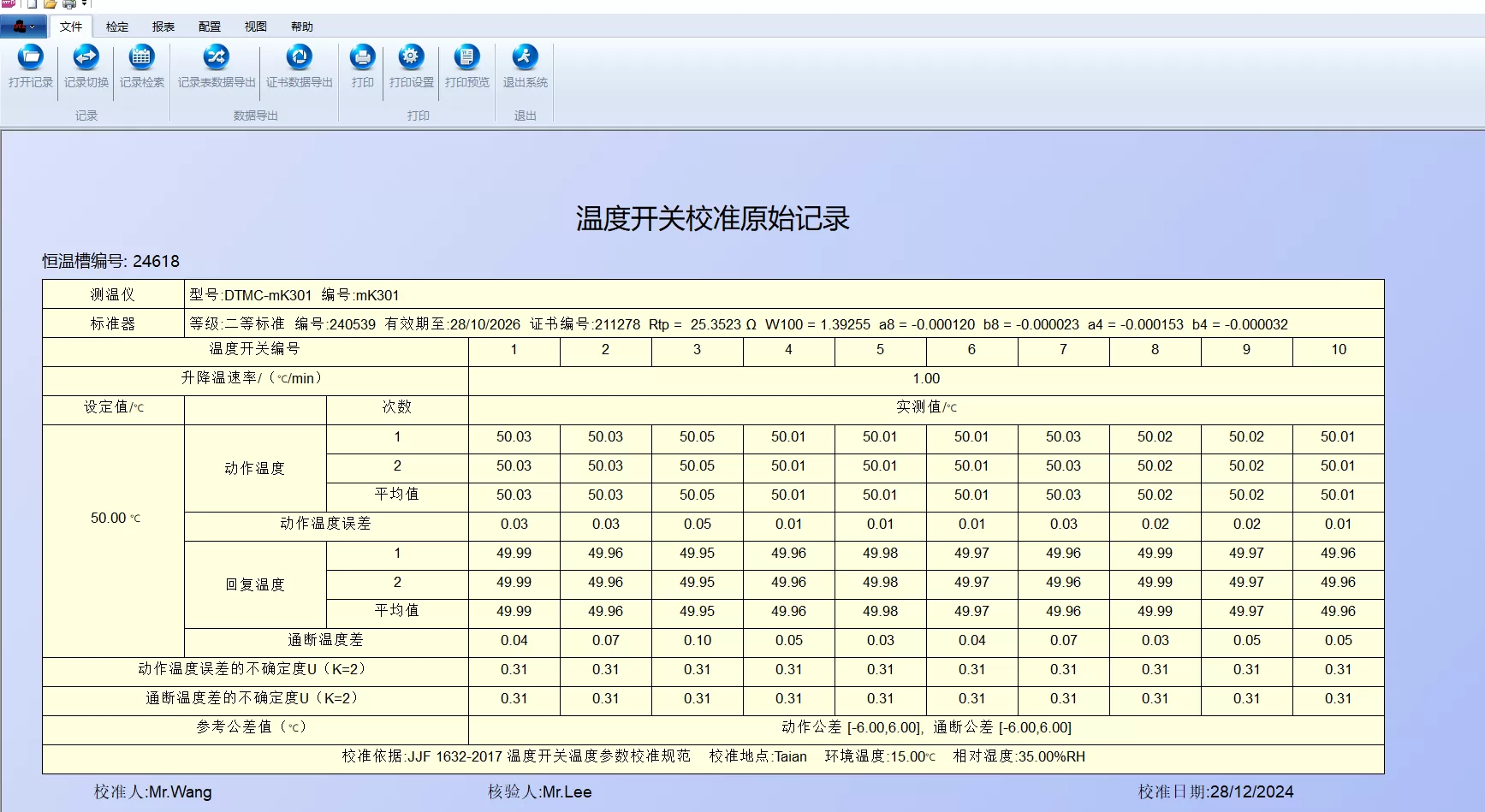

Automatically calculate the action temperature error, on-off temperature difference and effective range, and generate calibration results and certificates, and support the export, viewing, switching, retrieval and printing of certificates.At the same time, the original test data is Automatically saved to the folder, supporting export, view and reference, realizing the intelligent processing and standardized management of test data, and improving the efficiency and convenience of testing.

Intelligent data management and convenient inquiry

The system is equipped with a variety of keyword search function, which is convenient for users to query the history records at will.Detection data can be Automatically saved and recorded, and running data can be viewed in real time.The record table can record a number of information of each inspected temperature switch, including action temperature, average value of action temperature, error of action temperature, recovery temperature, average value of recovery temperature, difference of on-off temperature, and uncertainty calculation data, etc.

Features / Advantages

1.Flexible adaptation of multiple types of temperature switches

Compatible with various types of temperature switches such as active switches, passive switches, normally closed switches, normally open switches, etc.

2. Integrated standardized uncertainty calculation module

Strictly follow the metrological verification regulations "JJF 1632-2017 Temperature Switch Temperature Parameter Calibration Specification", built-in synthetic standard uncertainty and extended uncertainty automation calculation engine, Automatic implementation of the extended operation, to ensure that the results of the measurement uncertainty in full compliance with the mathematical model required by the regulations (k = 2), and to provide a traceable record of the computation process and the verification of the report generation function.

3.Highly accurate multi-channel data acquisition

Equipped with high-precision intelligent multi-channel pyrometer, the resolution of the standardizer data reading up to 0.0001; configuration of 10 channels at the same time calibration, to ensure the high accuracy and reliability of temperature measurement, to meet the stringent requirements of precision calibration.

4.Intelligent integration of equipment components

Temperature switch scanning device can be real-time power supply for the inspected switch, support manual and Automatic two test modes, and through the channel indicator lights synchronously display the switch action status, realizing the intelligent integration of power supply, test and status reminder to enhance the inspection efficiency and operation intuition.

5.Intelligent temperature control and condition detection integration

Real-time detection of changes in the state of the temperature switch and precise control of the temperature rise and fall. process of the thermostat tank, realizing the synchronous automation of temperature regulation and switch detection, ensuring efficient and accurate calibration process.

6.Integrated intelligent temperature rate control

Adopt PID regulation algorithm to implement dynamic rate constraints (≤1℃/min) for the heating/cooling process, through real-time power adjustment and temperature gradient monitoring, to ensure a smooth and controllable temperature change process, to avoid measurement errors caused by violent temperature fluctuations, and to meet the stringent requirements of the metrological calibration regulations for the rate of heating and cooling.

7.Intelligent Computing and Judgment Integration

Automatically calculate the action temperature error and on-off temperature difference of the temperature switch, and intelligently determine its effective range based on the preset standard, realizing the rapid analysis of the detection data and the determination of the results.

8.Enhanced temperature field stability control

Multi-order PID algorithm with real-time temperature feedback regulation mechanism is adopted to ensure that the system reaches the specified fluctuation threshold within the set time (≥10min) after entering the steady state from the heating stage, and maintains long-term stability through dynamic compensation strategy to meet the technical requirements of the metrological verification regulations on the stabilization time.

9.Real-time data and status monitoring

The interface displays and updates the standardizer data and task status in real time, providing intuitive operational feedback and dynamic information, ensuring that the user is always in control of the calibration process and key parameters, and enhancing operational convenience and transparency.

10.Dynamic tracking and history of temperature profiles

Real-time update of the temperature change curve, support for viewing the historical curve data, to help users visualize and analyze the temperature trend, providing visual reference and data traceability for the calibration process.

11.Easy wiring and remote expansion

Adopt simple wiring design, support ultra-fast sensor wiring, and reserved extension cable interface, to meet the needs of long-distance testing, significantly improve the convenience of field operation and adaptability of the test scenario.

12. Intelligent report generation and output

Automatically generates the testing record sheet, supports the export and printing of original records and calibration certificates, realizes the standardized management and convenient output of testing data, and meets the demand of standardized calibration process.

13.Efficient history search

Support a variety of keyword search function, users can quickly query the history records, to achieve the accurate positioning of data and flexible access to enhance the efficiency and convenience of data management.

14.Multi-protocol communication compatible

Support RS232, RS485, Type-C and other communication modes to ensure seamless connection and data transmission with various devices, meet the communication needs of diversified industrial scenarios, and enhance system adaptability and expandability.

Full parametercustomization

Support the user to set the calibration temperature, acquisition times, stabilization time, temperature distance, temperature rate, temperature switch type, number, model, temperature tolerance and manufacturer and other basic information, to provide a highly flexible configuration of the detection parameters, to meet the needs of diversified testing and personalized operating experience.

Intelligent management of standardizer information

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Intelligent monitoring and visualization of the whole process

The main interface of the system dynamically displays the current temperature of the standard and the thermostat tank, the set temperature, the temperature difference, the number of calibrations, the number of readings on the digital meter, the rate of temperature rise and fall, the inspected temperature point and the system running time and other key parameters, which achieves all-around real-time monitoring of the inspection process and data visualization, ensuring accurate and efficient operation.

Intelligent temperature control and real-time tracking of task status

The system Automatically determines the temperature switch status and accurately controls the temperature rise and fall of the thermostat tank, while the task bar real-time display of key information such as warm-up time, temperature rise time, temperature fall rate, interruption status and task completion, etc., realizing the intelligent management and dynamic monitoring of the testing process and ensuring the operation to be efficient and transparent.

Dynamic tracking and history of temperature profiles

Temperature change curve real-time update, you can view the history of the curve changes.

The curve interface updates the temperature data of the standardizer and the thermostat bath in real time.

Intelligent computing and reporting integrated management

Automatically calculate the action temperature error, on-off temperature difference and effective range, and generate calibration results and certificates, and support the export, viewing, switching, retrieval and printing of certificates.At the same time, the original test data is Automatically saved to the folder, supporting export, view and reference, realizing the intelligent processing and standardized management of test data, and improving the efficiency and convenience of testing.

Intelligent data management and convenient inquiry

The system is equipped with a variety of keyword search function, which is convenient for users to query the history records at will.Detection data can be Automatically saved and recorded, and running data can be viewed in real time.The record table can record a number of information of each inspected temperature switch, including action temperature, average value of action temperature, error of action temperature, recovery temperature, average value of recovery temperature, difference of on-off temperature, and uncertainty calculation data, etc.

Enter your inquiry details, We will reply you in 1 hours.

Send