Thermocouple And Thermal Resistance Automatic Calibration System

Product Features

During the verification process, manual intervention is unnecessary.

Advanced expert PID algorithm is adopted to effectively prevent the overshoot in the temperature control process.

The software can operate independently, and can be compatible with cryotemperature bath and thermostatic oil bath.

ITS 90 international temperature standard conversion software can be provided

Model Selection

Request a Quote

Or whatsapp +8618853850621

Description

Download

Product Description

DTZ-01AG Thermocouple And Thermal Resistance Automatic Calibration System is automated verification equipment integrating the computer technology,electronic technology and automatic testing technology.The system is mainly used for the automatic verification/calibration of primary and secondary temperature instrument.In the system,the multichannel low-potential scanner,digital multimeter,thermocouple verification furnace,thermostatic bath and other devices are control by computer,which can realize the full automation of temperature control,data acquisition,data process,report generation,data storage and print in the process of verifying/calibrating the primary and secondary temperature instrument.The system functions and technical indexes fully conform to relevant national verification procedures and follow the ITS-90 international temperature scale.

Product characteristics

1. This thermocouple verification system can be used for the automatic verification / calibration of the standard thermocouples / precious metal thermocouples with different scale numbers of S, R and B.

2. During the verification process, manual intervention is unnecessary.Realize the complete automation to control temperature, data detection, data processing, generate various verification reports, storage and database management in the verification process.

3. The temperature control system adopts the imported intelligent PID regulator with RS485 communication function as the temperature controller.Advanced expert PID algorithm is adopted to effectively prevent the overshoot in the temperature control process.

4. The software can operate independently, and can be compatible with cryotemperature bath and thermostatic oil bath, and thermocouples for different scale numbers. Normal verification of communication, control and collection can be realized in the verification process.

5. The system has mixed verification function, which can realize hybrid verification of different scale number standard thermocouples in the same furnace.

6. ITS 90 international temperature standard conversion software can be provided: through mobile APP, universal thermocouple, industrial thermoelectric resistance, standard platinum resistance, and temperature transmitter can be convenient to achieve power value and temperature conversion; The PC terminal can achieve the conversion of the temperature unit; Conversion of operating thermocouple temperature and potential values (including WRe3 and WRe5), And the differential thermal potential can be calculated; Conversion of industrial thermal resistance temperature value and resistance value, And the differential thermal power resistance can be calculated; Calculate the potential value of the standard even 300℃-1300℃ and the conversion of the potential value and the temperature value within the range according to the standard certificate; Seek the temperature value or the resistance value according to the standard certificate value; Dry and wet ball humidity conversion; Conversion of the heat transfer coefficient; Heat transfer speed conversion; Conversion of power units, pressure units, diffusion coefficient, length units, area units, surface tension, speed units, force units, power viscosity, motion viscosity, and energy units.

7. The verification system shall meet the requirements of JJF1098-2003 Calibration Code for Thermocouple and Automatic Thermal Resistance Measurement System and other relevant codes and specifications.

Function and Feature

| Verification/Calibration Function | Indexing Number | Grade | Notes |

|---|---|---|---|

| Standard Thermocouple | S,R,B | Class I,and Class II | Standard thermocouple |

|

Thermocouple for Working |

S,R,Short S, Short R |

Grade I and II | Precious metal thermocouple for working |

| B | Grade II and III | ||

| Grade K,N,E,J,T,EA-2 | Grade I,II,and III | Base metal thermocouple for working | |

| WRe3-WRe25,WRe5-WRe26 | Tungsten rhenium thermocouple for work | ||

| Industrial Thermistor | Pt100,Pt10,Cu50,Pt-X,Cu-X | Grade AA,A,B,and C | Two-wire,three-wire,and four-wire system |

| Temperature Transmitter | 0-10mA,4-20mA,1-5V | With thermocouple and thermistor | |

|

Precious Metal Thermocouple Wire |

S,R | Standard Grade(Class I and II),Grade I and II |

Previous metal thermocouple wire |

| B | Standard Grade(Class I and II),Grade I and II | ||

| Platinum Rhodium Thermocouple Wire | S,R,B | ||

| Base Metal Thermocouple Wire | K,N,E,J,T | Grade I,II,and III | Base metal thermocouple wire |

| Platinum Wire for Electrical Resistance Thermometer | Pt25,Pt100,Pt10 | Standard Grade(Class I and II),Grade A and B | Platinum wire for electrical resistance thermometer |

| Expansion Thermometers | Standard mercury-in-glass thermometer,liquid-in-glass thermometers for working,bimetal thermometer,and pressure type thermometer | ||

| Secondary Temperature Instruments | Moving-coil temperature indicator regulator,digital temperature indicating regulator,industrial process measurement recorder | ||

Technical Indexes:

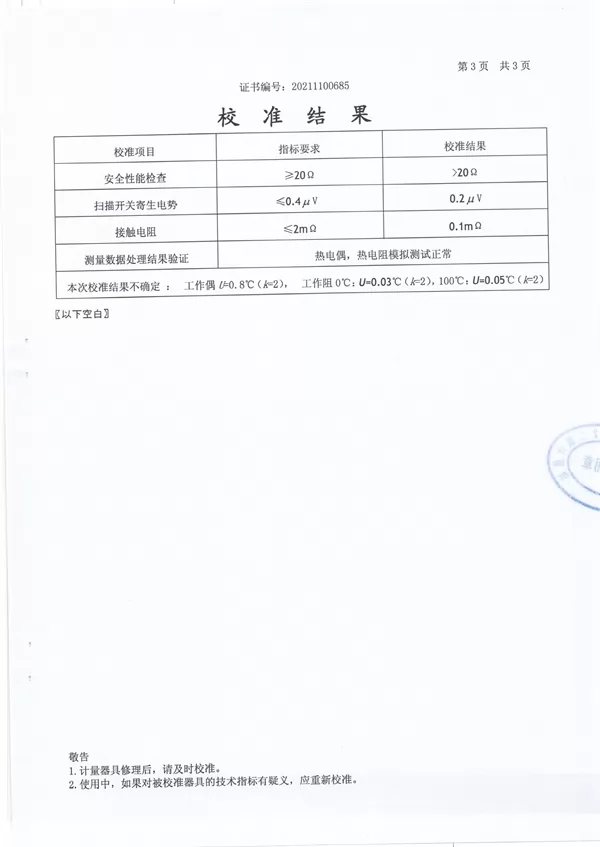

■ Multichannel scanning of parasitic potential in switch:≤0.2μV

■Difference value of inter-channel data acquisition:≤0.5μV 1mΩ

■Repeatability measurement: ≤1.0μV 3mΩ

■Thermostatic performance of thermocouple verification:

Constant temperature≤0.5℃/6min,and measurement≤0.1℃/min

■Thermostatic performance of thermostatic oil and water bath:

Constant temperature≤0.02℃/10min,and measurement≤0.01℃/min

■Compensation range of thermocouple reference end:0℃-50℃,resolution:0.01℃

Product advantages

High-efficiency Working Mode

■Mixing verification:The system can realize the mixing verification of base metal thermocouples with different indexing numbers in one same furnace.

■Grouping verification:The low-temperature thermocouple and thermistor can be verified in group,wherein 10 groups(100 pieces)can be verified in one batch.

■Mandatory verification:The system can perform the quick mandatory verification as user requires.

■The special positioning device for verification furnace can make quick position for the furnace charging of thermocouple,to guarantee the accuracy of furnace charging position.

■Advanced temperature control mode is adopt,so the constant temperature source has a high rate of temperature increase and good stabilization effect,which can reduce the verification time and improve the working efficiency.

■The system can be upgraded to multi-furnace group-control system if the verification quantity is large.

Complete Safety Mode

■Both the imported intelligent instrument and software are used for double temperature control protection with the function of over-temperature protection and power down protection.

■Self-inspection and line inspection:It can make humanized preventive protection for the open circuit,reverse connection and other protection on the standard and inspected wiring.

■The software supports multimedia audible alarm and prompt,and allows customer to customize the alarm and prompt sound of various events.

■Standard cabinet is adopted,and separate treatment is used for the the motive power source and signal control part to avoid the problem of signal interference.

Flexible and Diversified Configuration

■ It supports multiple models of digital meter communication.

■ It is compatible with the constant temperature source from different manufacturers.

■ The verification temperature point of thermocouple can be the procedure default value,or be set as any point value as the customer requires,such as 660.5°C.

■ The reference end treatment can be compensated by ice point thermostat or automatically compensated by the temperature sensor for reference end.The temperature sensor for reference end uses Grade A Pt100 platinum resistor which has stable reading and high measurement accuracy,and is easy to be corrected.The correction value can be input into the software,to improve the measurement accuracy.

Graphical Software Operation Platform

■ The software can be operated perfectly in the Windows series of operation system,and the system has the user interface in Chinese with simple operation.

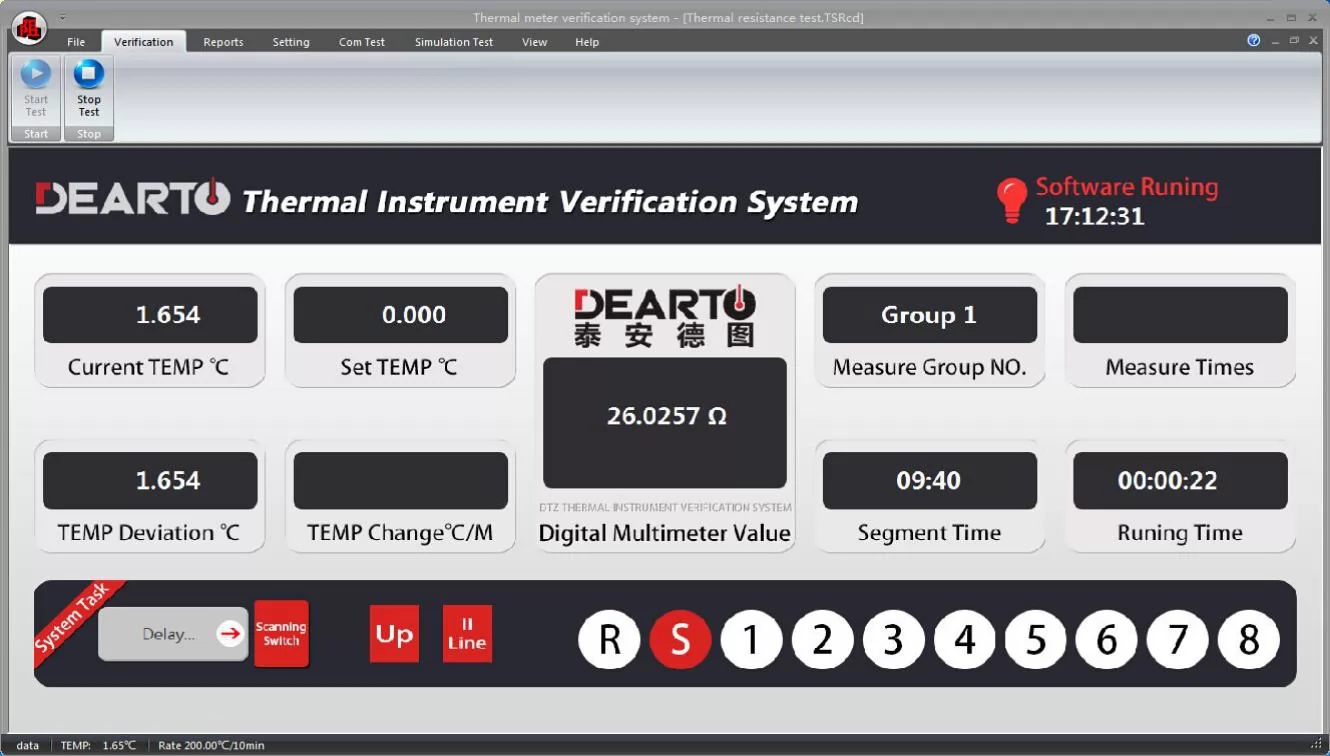

■ Rich display interface:it displays the verification data and temperature control cure in real time,and can automatically track and display all state information of all verification furnaces,thermostatic baths,and standards,which is convenient for the measuring personnel to control the equipment operation status in real time.

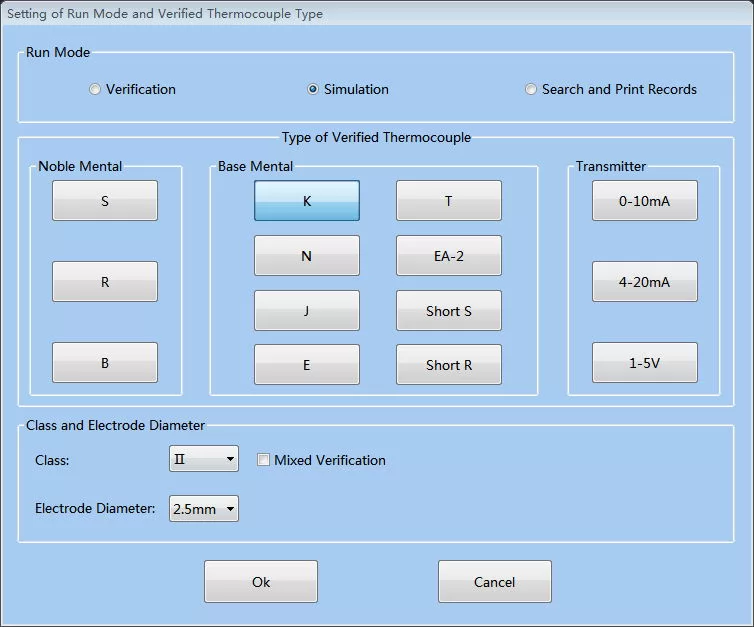

■ Simulating verification:the whole verification process is simulated by software,which can be used for study and demonstration.

■ Both the software and hardware product have the fully proprietary intellectual property rights,so the upgrade service is guaranteed for providing all-around services for customers.

Modular Data Management Function

■ It has strong data acquisition,data analysis and process,report management,data query,equipment self-inspection and other functional modules.After the verification is completed,all raw data,verification certificate will be automatically stored into the database,and user can query and print the raw record and report through the condition query function.And it comes with the memory function for directly calling the inspected information in next verification.

■ The system data backup function has two modes:manual backup and automatic backup,for easier metrological tracing.

Stable and Reliable Product Performance

■ The Company has passed the certification of ISO9002:2008 International Quality Management System and strictly executes it.Its products meet the national industrial standard from raw material selection,production and processing to the finished products,which meets the requirements of AMS 2750E High-temperature Measurement in the mean time of being superior to China's domestic specifications.

Software Secondary Development Function

■ Users can design the format of table and certificate by themselves according to requirements.The existing software can be customized and modified according to user's requirements.Relevant interfaces are provided to realize the secondary development of software and meet users'own requirements.

Multi-channel low potential scanner

■ It adopts the fully sealed low-potential scanner switch driven by stepper motor,and its switch substrate uses large-area sliver coated material,which is dustproof,wear-resisting and anti-oxidative;the wiring terminal is in pure red cooper materials which are produced in one same batch.It guarantees the parasitic potential to be≤0.2μV for long time.

■ It contains change-over switch in four-wire system which effectively eliminate the impact of parasitic potential in measurement circuit on the measurement result through its special forward and backward measurement switch function.

■ It adopts color touch screen,and is internally installed with user guide,so the customer can query the system instructions for use at any time without looking over the user manual,including the wiring method of thermocouple and thermistor detection,and other functions;it can display the real-time position and state of the standard and inspected channel,switch the position of standard and inspected channel;manual verification can be applied when being disconnected with the upper computer.

Integrated Junction Board

■ The system junction board and three-wire resistance convertor are in integrated design,which is compatible with the wiring connection of thermocouple,thermistor in two-wire system,thermistor in three-wire system,and thermistor in four-wire system.It can automatically complete the measurement function switch between 2 internal leads contained and 1 internal lead contained during the verification of thermistor in three-wire system.

Professional Data Processing Capacity

■ The system meets the existing national procedures and specifications,and the data is computed and processed strictly in accordance with the procedures and specifications to ensure accurate and reliable verification result.

Uncertainty analysis software

■ The uncertainty analysis software is a software for analyzing the calculation uncertainty.It can calculate the uncertainty of the DTZ-01 thermocouple,the thermal resistance automatic verification system,or other thermocouple thermal resistance automatic verification system,and can export the results.

Free professional temperature scale conversion software

■ It can realize the conversion of temperature unit;the conversion of temperature value and potential value of working thermocouple(including WRe3 and WRe5),and can calculate differential thermoelectric potential;conversion of industrial thermal resistance temperature value and resistance value,and can calculate differential thermal resistance;Calculate the potential value of the standard even 300℃-1300℃ according to the standard certificate and the conversion of the potential value and the temperature value within the range;according to the standard certificate value,the standard thermal resistance is obtained from the resistance value or the temperature value is obtained;the dry and wet bulb humidity Conversion;heat transfer coefficient conversion;heat transfer rate conversion;power unit,pressure unit,diffusion coefficient,length unit,area unit,surface tension,speed unit,force unit,dynamic viscosity,kinematic viscosity,energy unit conversion.

Enter your inquiry details, We will reply you in 1 hours.

Send