Surface probe calibrators are devices that are used to calibrate temperature sensors. These sensors are typically used to measure the temperature of surfaces, such as walls, floors, and other objects. The accuracy of these sensors is critical, as even small errors in temperature measurement can have a significant impact on the performance of industrial processes, scientific experiments, and other applications.

Calibrating surface sensors is important to ensure that they are providing accurate temperature measurements. If a sensor is not calibrated properly, it may give inaccurate readings, which can lead to errors in processes or experiments. This can result in wasted time, resources, and money, as well as potential safety hazards.

How Does a Surface Probe Work?

Temperature sensors work by measuring the heat that is given off by an object. Surface probe calibrator devices are designed to measure this heat and provide accurate temperature readings. There are several types of surface probes, including thermocouples, RTDs (resistance temperature detectors), and thermistors.

Thermocouples work by measuring the voltage generated when two dissimilar metals are joined at one end and exposed to a temperature difference. RTDs measure the change in electrical resistance of a material in response to temperature changes. Thermistors measure changes in electrical resistance due to temperature changes as well, but use a different type of material than RTDs.

When a surface probe is placed on a surface, it measures the temperature of that surface by detecting the heat that is being emitted by the surface. The probe then converts this heat into an electrical signal, which can be read by a thermometer or other measuring device.

Overall, surface probes work by detecting the heat given off by an object and then converting this heat into an electrical signal that can be read and analyzed.

What is surface probe calibration?

Surface probe calibration is the process of adjusting a temperature sensor to ensure that it provides accurate temperature readings. This process involves comparing the temperature readings of the surface probe to a known reference temperature. Any discrepancies between the two temperatures are then used to adjust the calibration of the probe.

The calibration of surface temperature probes is important for ensuring accurate temperature measurement. Over time, temperature sensors can drift out of calibration, resulting in inaccurate readings. Calibration should be performed regularly to ensure that temperature sensors remain accurate and reliable.

How to calibrate a surface probe?

Calibrating a surface probe is a relatively straightforward process that involves the following steps:

1. Obtain a reference temperature source. This could be a water bath, an ice bath, or a calibration device specifically designed for temperature calibration.

2. Place the surface probe on the reference temperature source and wait for the temperature reading to stabilize.

3. Compare the temperature reading on the surface probe to the known reference temperature.

4. If the readings do not match, adjust the calibration of the surface probe until the readings match the known reference temperature.

5. Repeat the process with multiple reference temperatures to ensure the accuracy of the surface probe across a range of temperatures.

Probe calibration methods

There are several methods that can be used to calibrate surface temperature probes, including:

1. Ice bath method: This method involves placing the surface probe in an ice bath and comparing the temperature reading to the known the freezing point of water

2. Boiling water method: This method involves placing the surface probe in boiling water and comparing the temperature reading to the known boiling point of water.

3. Dry block method: This method involves using a calibrated dry block to provide a known reference temperature to compare against the surface probe reading.

What does sensor calibration do?

Sensor calibration ensures that temperature sensors are accurate and reliable. Calibration adjusts the temperature readings of the sensor to match known reference temperatures, allowing the sensor to provide accurate temperature measurements.

Calibration affects surface temperature probe accuracy by adjusting the sensitivity of the probe to temperature changes. When a sensor is calibrated, it is able to detect smaller temperature changes, resulting in more accurate temperature readings.

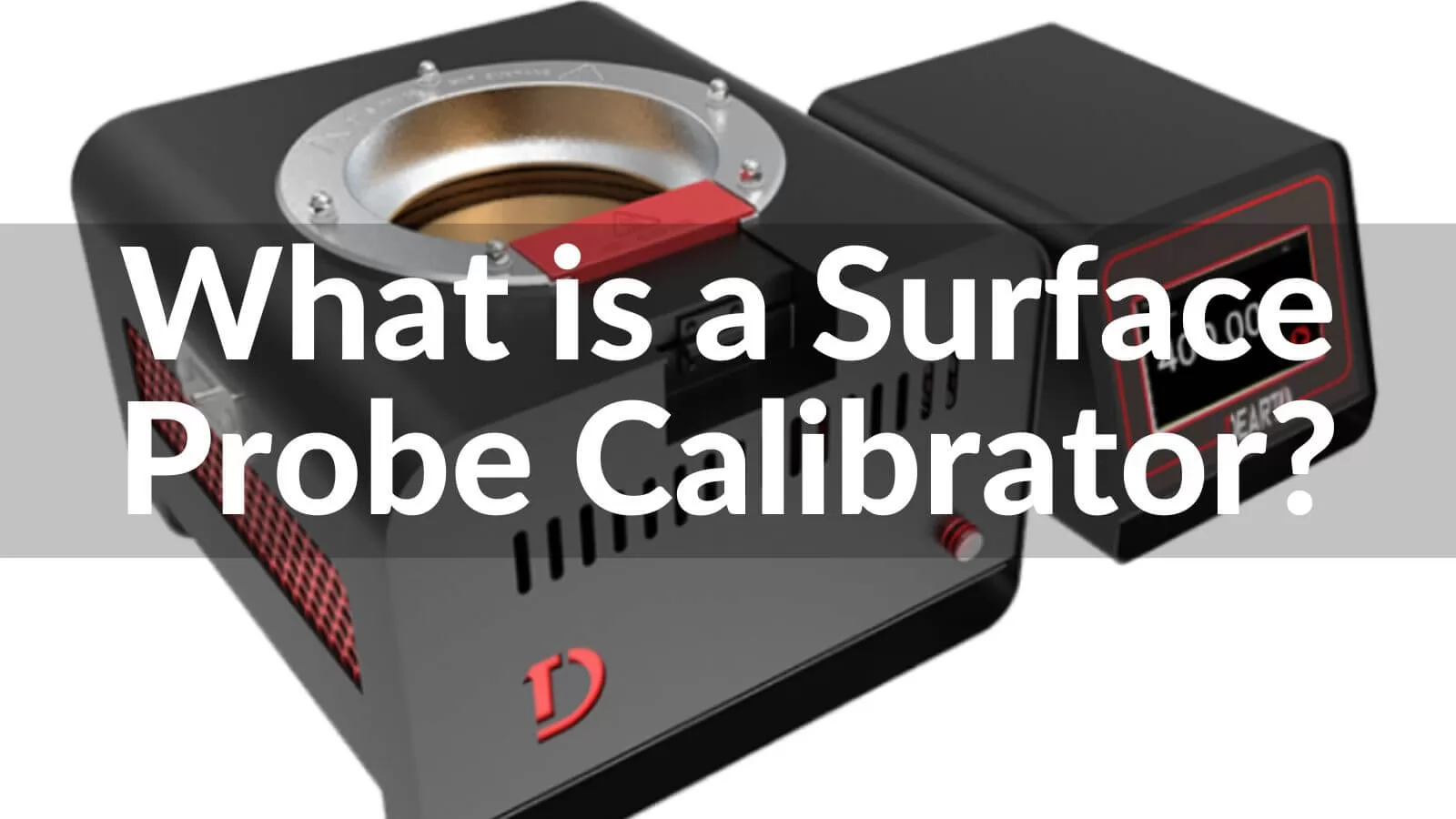

Popular Surface Probe Calibrators

Surface Probe Calibrator 50℃~500℃

● Wide temperature range, multiple range options: 35~400℃ /50~500℃/ 50~600℃

● High calibration plane size, up to 130 mm ± accuracy 0.5℃@200℃

● Stable temperature control ±0.3℃/10 min(@300℃)

● High resolution 0.01℃

Surface Probe Calibrator 50℃~600℃

● Wide temperature range: 50~600℃

● Oversized working area size: 130mm

● High resolution 0.01℃

● Aerospace composite coating, good wear resistance, high thermal conductivity

Types of Surface Probe Calibrators

When it comes to ensuring accurate measurements and reliable data in various industries, surface probe calibrators play a vital role. These devices are designed to calibrate and validate the performance of surface sensors, enabling precise temperature measurements in different environments.

1. Thermocouple Calibrators

2. RTD Calibrators

3. Infrared Calibrators

4. Digital Thermometer Calibrators

Surface Probe Calibrator Prices

When considering the purchase of a surface probe calibrator, it is essential to have a clear understanding of the pricing options available. Surface probe calibrators come in various models and configurations, each with its own features and capabilities, which can affect the overall cost.

Price Range of Surface Probe Calibrators:

As a rough estimate, basic handheld calibrators with limited functionalities can start from around $100 and go up to $500, depending on the brand and quality.

For more advanced and feature-rich benchtop calibrators, the price range can be between $500 and $2000. These calibrators offer precise temperature simulation, multiple channel capabilities, and additional features like data logging, communication interfaces, and advanced calibration algorithms.

Industry Applications of Surface Probe Calibrators

Surface probe calibrators are versatile tools that find applications in a wide range of industries where accurate temperature measurements are critical. These calibrators play a crucial role in ensuring the reliability and precision of surface temperature sensors.

1. Manufacturing and Industrial Processes

In the manufacturing sector, surface probe calibrators are indispensable for maintaining quality control and optimizing production processes. They are used to calibrate temperature sensors in various equipment and systems, such as ovens, furnaces, extruders, and heat treatment chambers. By ensuring accurate temperature measurements, surface probe calibrators help prevent defects, improve product consistency, and enhance overall production efficiency.

2. Pharmaceutical and Healthcare

The pharmaceutical and healthcare industries rely on precise temperature monitoring for critical processes, such as storage, transportation, and production of medications, vaccines, and biological samples. Surface probe calibrators are used to calibrate temperature sensors in refrigerators, freezers, incubators, and sterilization equipment, ensuring that temperature-sensitive products and samples are maintained within the required temperature ranges.

3. Food Processing and Storage

The food industry relies heavily on temperature control to ensure food safety and quality. Surface probe calibrators are widely used to calibrate temperature sensors in food processing equipment, storage facilities, and transportation containers. By accurately calibrating temperature sensors, these calibrators help maintain optimal storage conditions, prevent spoilage, and ensure compliance with food safety regulations.

4. Research and Development

In research and development laboratories, surface probe calibrators play a crucial role in validating temperature sensors used in various scientific experiments and studies. These calibrators are used to calibrate temperature sensors in environmental chambers, climate-controlled chambers, and test setups for accurate and repeatable temperature measurements.

5. Energy and Environmental Monitoring

Surface probe calibrators are also employed in the energy sector and environmental monitoring applications. They are used to calibrate temperature sensors in energy production facilities, such as power plants and renewable energy systems, ensuring efficient operation and accurate performance monitoring.

Conclusion

Surface probe calibrators are important devices that are used to calibrate temperature sensors. Calibrating surface sensors is critical to ensuring accurate temperature measurements, which are necessary for a wide range of industrial, scientific, and other applications. Surface probe calibration involves comparing the temperature readings of a surface probe to a known reference temperature and adjusting the calibration of the probe as needed.

Regular calibration of surface temperature probes is essential for ensuring accurate temperature measurements. By following the proper calibration procedures and using the right calibration methods, you can ensure that your surface probes provide accurate and reliable temperature readings.

Related Articles

Dry Block Calibrator vs Temperature Bath