Wireless Furnace Temperature Tracking Detection System

Product Features

Time mark between any two points

Label the slope between any two points

Temperature labeling at any point in time

Any position, any range of curve zoom display

Temperature difference curve display within any time range

Complete process analysis report PWI

The software clears the memory data of the instrument

Model Selection

Request a Quote

Or whatsapp +8618853850621

Description

Download

Product Description

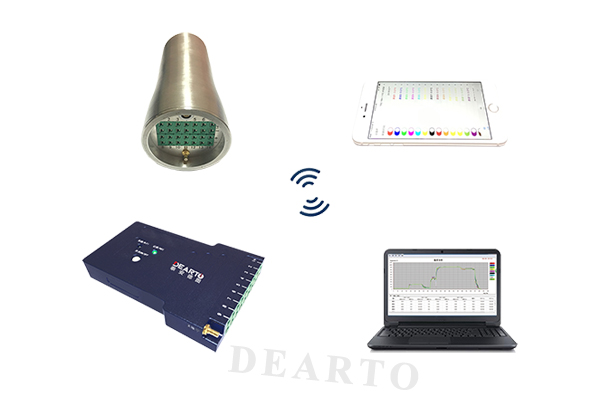

DTZ-500G wireless furnace temperature tracking detection system is composed of high temperature resistant thermometer, heat insulation box, high temperature resistant thermocouple and wireless terminal. The main working principle is to put the furnace temperature tracker and the painted workpiece into the furnace to be heated synchronously, record the curing temperature of the workpiece itself and the temperature of the furnace gas during the coating process in real time, and display the temperature in real-time through mobile phones, ipads or computers. In order to understand the changing relationship of the entire temperature in the production process and the temperature uniformity difference of the furnace.

Technical Indicators

| Channels | 18 channels | Precision | ±0.4℃ | Sensor | K、N、S、T | Temperature range | 0 to 1300℃ |

|---|---|---|---|---|---|---|---|

| furnace time | Customized according to usage scenarios | Memory | 8GB (large memory, can store data permanently) | ||||

| The sampling period | 1s to 60s, can be set according to the test requirements | ||||||

| Battery | Rechargeable polymer lithium battery 2200mAh can be used continuously for 50 hours, and it can be used after 15 minutes of quick charging. If wireless is turned on, it can last for 13 hours on a single charge | ||||||

| Computer requirements | Windows 98, 2000, XP, vista, win7, etc., can be connected to print out the temperature curve | ||||||

| Insulated box size | Customized according to usage scenarios | ||||||

| Instrument Description |

The main chip of the instrument: the temperature-sensitive high-resolution host chip imported from the United States Insulation material: Nano insulation material imported from Germany Shell: high temperature resistant, corrosion resistant stainless steel Thermocouple sensor: National Standard Class I For specific parameters, see the technical solution according to the usage scenario |

||||||

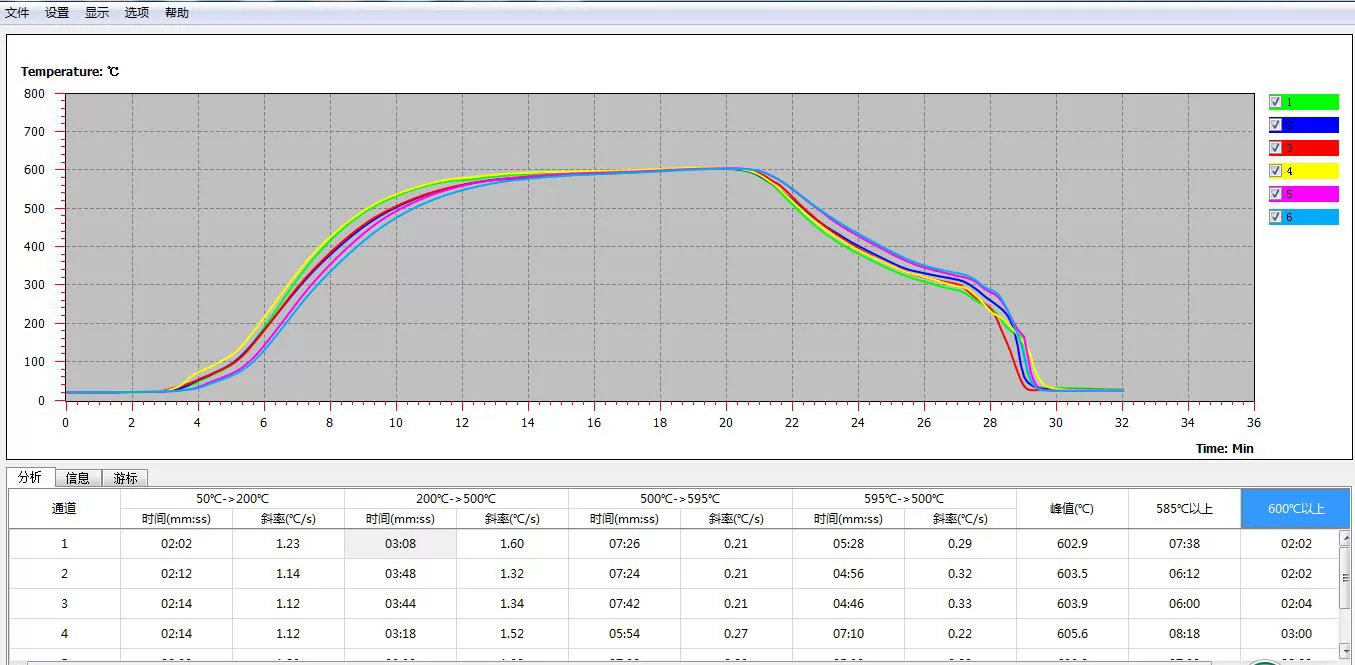

Software Features:

1. The name of the temperature sampling point and the schematic diagram of the PCB or workpiece

2. Time mark between any two points

3. Label the slope between any two points

4. Temperature labeling at any point in time

5. Set the background temperature curve to compare multiple sets of curves

6. Any position, any range of curve zoom display

7. Temperature difference curve display within any time range

8. Four cursor lines calculate various temperature values in the specified interval

9. Complete kiln database (SMT) / temperature control scheme (heat treatment), equipment database

10. Complete process analysis report PWI

11. Simulation curve function, process optimization, test date and time

12. Output of company name, product name and remark information processing

13. It can directly print the test report or output the test report in an electronic file

14. The software clears the memory data of the instrument

15. Time Compensation

16. Temperature statistics

Product Features:

- This instrument adopts an imported TF memory chip, and any accident will not lose data

- Simultaneously store 8G group data, exceeding automatic coverage;

- One-button operation, manual, temperature, and time start, simple and quick to use, self-developed full Chinese setting and data analysis software, the operation is clear at a glance.

- In addition, the upgraded version of the instrument can be connected wirelessly through a PC or ios system mobile terminal to display temperature curve data in real-time.

PC software curve chart

Temperature Measurement Process:

- According to the customer's requirements and the use environment, use a furnace temperature tracker to measure the temperature, connect the thermocouple, put it in the heat insulation box, and cover the heat insulation box to prevent heat leakage.

- Turn on the mobile phone, iPad, or desktop computer to control the furnace temperature tracker in real-time and analyze the temperature data in real-time.

- In order to obtain the real heating temperature of the part, the thermocouple is fixed on the part

- After the heat treatment is over, the recorder is taken out after the thermal insulation box has cooled down.

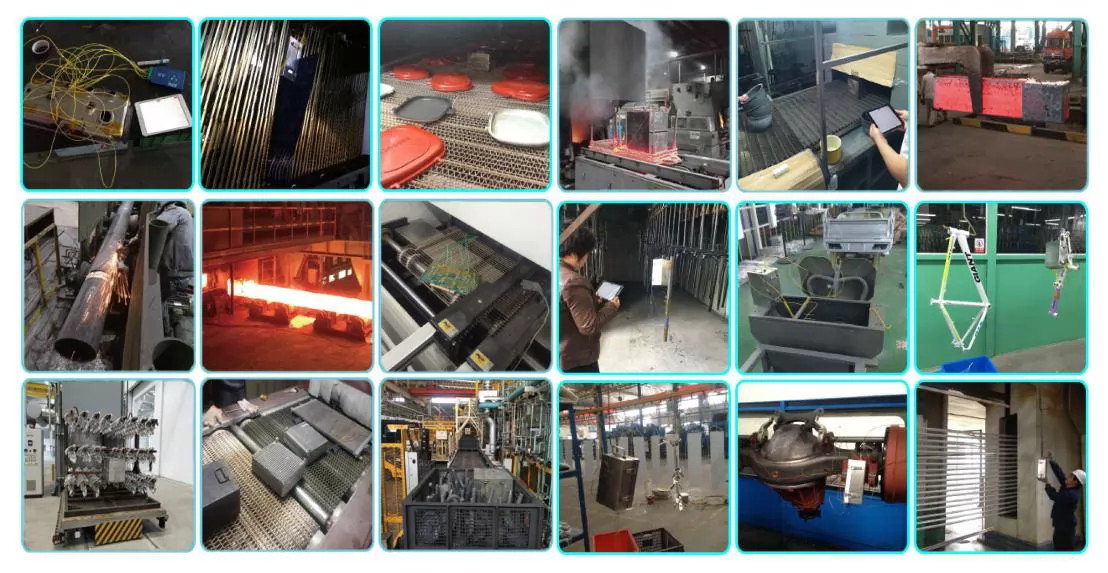

The Main Purpose:

- Digitalization of the coating process, determination of different curing temperature systems and real-time temperature curves, heating temperature and temperature difference.

- Test the curing temperature and temperature difference of the workpiece under different temperature systems and different output conditions.

- Furnace temperature uniformity test.

Use Scene Graph:

Enter your inquiry details, We will reply you in 1 hours.

Send